1) This dyeing programmer is developed with the latest integrated chip and can technically compete with any instrument in the semiautomatic category .Due to the compact size of the programmer; it is suitable for any small dyeing machine and lab machine which contains a small control panel. This instrument controls seven outputs which are heat in, cool in, forward and reverse direction of the motor, air in, air out and alarm.

2) The RS485 communication with the computer makes it possible to watch the progress of the programs through the PC, to modify or execute a program through computer keyboard and even to take a printout of the temperature graph of entire the executed program.

3) Direction of the main pump can be controlled with this instrument. It is possible to run the motor in a single direction or dual direction as per the requirement. The timer always starts with the pause time which ensures the safety of the pump.

4) The programmer also has inching facility for the lab machine which helps to move the direction of beaker in an appropriate position after the process.

5) Temperature calibration has been done digitally through software. It is not required to calibrate the temperature every year as it is guaranteed for at least five years. The calibration cannot be altered by anyone on the site as it is protected with a password.

6) It records all the information about the process in a separate location and any time enables to check the data regarding total executed time, number of programs started and finished, total ON time of the instrument, last technical error, number of power failed during the process . It can also read the temperature and input DC voltage of the microprocessor. .Moreover it has a digital serial number which can not be altered.

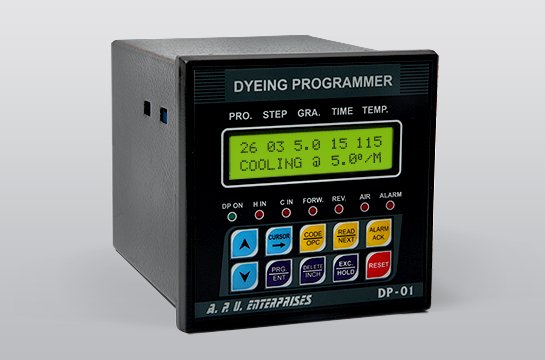

7) The first row of the LCD display shows the current status of the parameter and second row shows the messages like remaining period of the hold time, rate of heating or cooling and also displays the message for improper rate.

8) Proportionate band, overshoot control during the hold time, operator call and auto restart in case of power failure are the extra features of this programmer. Duration of the alarm, forward and reverse direction of the motor and air pressure can be controlled with adjustable parameter.

9) Main hardware like front keyboard, output connectors, relays, IC and other electronic components of this instrument are supplied by highly prominent companies in Asia. Hence this programmer can match with any world class instruments in terms of quality

SPECIFICATIONS

Resolution: 1 degree.

Accuracy: 1 degree

Input supply: 160-250 VAC.

Details of out put relay: SPDT, Goodsky RWH-SH-112D, Load 1Amp/240VAC.

Output connector: Phoenix Contact, Part No: MVSTBW, MSTBVA and MSTB

Size of the enclosure: 96x96x110, Cut out of panel 92x92.

Temperature range: 0-150 degree.

LCD: 16/2 alphanumeric LCD

Temperature sensing probe: PT 100

Status indication: LED for relay status

Sensor breaks protection: Auto switches off on sensor break, PT 100 OPEN / SHORT will be displayed.

Rate of heating / cooling is adjustable from: 0.5 to 9.5 degree in step of 0.5 degree

Number of programs: 50 programs with 25 steps.

Service & Support

We provide one year guarantee for all our electronics instruments against any manufacturing defect but the same will not be covered in case of mishandling by someone or any problem arisen due to fire, water, electric short circuit or any other natural calamity.

Our engineer attends the complaints in Mumbai and the surrounding areas at site. But for any complaints from other parts of the country, the instrument has to be sent to our Mumbai office for repairing. After rectifying the problem the same will be returned through a fastest courier to the customer's destination.

Regarding any complaints customers can contact us during the normal business hours 10AM-6PM) , from Monday to Saturday on any number mentioned in "Contact us". Complaints can also be registered through an email at support@apuenterprises.com